- Factory Direct Sale

- Quality Assurance

- Quick Response

- Service Without Worry

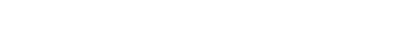

Banana Sieve

Processing Capacity:160-1350m³/h

Feed Particle Size:≤300mm

Applicable Materials:Large and medium-sized materials

Application Scope:Stone factories, mines, metallurgy, building materials, roads, railways, etc.

- +8613503852957

- 7 * 24-hour Service Hotline

Banana vibrating screen

The banana screen is a masterpiece that combines more than ten years of vibration equipment design and manufacturing experience of Zhongyi Mining Machinery with modern design and manufacturing technology. The structure of the whole machine has been optimized and designed by the Sino-Italian engineering team, using high-strength wear-resistant materials and processing technology standards. It is suitable for stone factories, mining, metallurgy, building materials and other fields. At present, Zhongyi Banana Screen has been used in multiple sand and gravel projects, and its advantages such as large output and stable operation have been well received by users.

Banana vibrating screen product display

Banana screen, also known as linear equal thickness vibrating screen, is named after its long shape like a banana. Its screen box is similar to the shape of a banana, and the screen surface is composed of several sections with different angles. Compared with traditional sieves of the same specifications, the banana vibrating screen has a larger processing capacity, and its processing capacity per unit area is 1.5 to 2 times that of traditional grading sieves. It is a vibrating screen with better performance at present. It is mainly used for particle size classification of large and medium-sized materials with high fine particle content. It can also be used for dehydration, demediation and desliming operations (fine particles refer to particles whose particle size is less than half of the sieve hole size).

Various models of banana vibrating screens meet different needs

Advantages And Characteristics

1. Simple and compact structure, high strength, balanced force distribution, and large safety factor;

2. The vibration parameters should be set reasonably to avoid the natural frequencies of the screen body at all levels and reduce the impact of resonance;

3. Long life, the screen body has a service life of up to 10 years, and the vibrator has a service life of more than 60,000 hours;

4. Light weight, low power consumption, high vibration intensity (9-12mm), and high screening efficiency (>95%);

5. Use the screen surface configuration from a large manufacturer to achieve high screening efficiency and large material handling capacity;

6. Low working noise, the noise level is less than 75 decibels, and the operation is stable;

7. Use imported professional frequency analyzers for frequency response and dynamic analysis;

8. Complete varieties, able to fully meet the screening process requirements of different material characteristics and processing volumes;

9. The screening machine is easy to operate and maintain, safe to use, cost-effective, has sufficient spare parts, and provides timely and thoughtful service.

Working Principle

Banana vibrating screen is mainly composed of screen box, screen mesh, vibration exciter, damping spring and lower frame. It uses a motor and an exciter as the vibration source. The exciter is mainly composed of an eccentric shaft, a pulley, a bearing and a bearing seat. The exciter is installed on the side plate of the screen box and is connected by the motor through a triangle belt or soft connection. Connected to it, the motor drives the eccentric shaft to rotate, generating centrifugal inertial force and forcing the screen box to vibrate.

There is a slope at the feed end, starting at 34°, and then descending at a certain angle to the discharge end of about 10°. The screen surface adopts the form of fold lines with different inclination angles, and the thickness of the material layer does not change from the inlet end to the outlet end. The ratio of the material amount to the flow rate on each section of the screen surface is stable, the material layer is high, and the screening efficiency is significantly improved. It is 1-2 times higher than the processing capacity of the screener with the same effective area. For materials with high fine particle content, especially When the content of materials whose medium content accounts for less than 1/2 of the classified particle size is large, the banana-type vibrating screener has higher screening efficiency.

Technical Parameter

| Model | Feeding particle size(mm) | Number of vibrations(rpm) | Double amplitude(mm) | Power(KW) | Throughput(m3/h) |

| BS3673 | ≤300 | 970 | 8-12 | 2x22 | 160-750 |

| BD3673 | 970 | 2x30 | 190-800 | ||

| BS3685 | 970 | 2x22 | 200-800 | ||

| BD3685 | 970 | 2x30 | 240-1100 | ||

| BS4385 | 970 | 2x30 | 240-1100 | ||

| BD4385 | 980 | 2x37 | 300-1350 | ||

| BS4997 | 980 | 2x37 | 300-1350 | ||

| BD4997 | 980 | 2x45 | ?340-1600 |

Recommended Products

Customized Service Process

You can also contact us for more models and support customization

-

Consulting Customer Service

You only need one phone call,

Consult now

leave the rest to us -

Understand Requirements

Sales team to talk to you in detail.

Provide Requirements

Tell us about your needs -

Planning And Design

Professional engineers provide reasonable solutions

Get the solution

based on your needs -

Production-Manufacturing

We will complete the quality

Scheduled equipment

within a reasonable time -

Technical Installation

Technical installation professional installation team on-site installation

Technical support

Debugging to stable production -

Late Maintenance

If you have any questions in the later stage,

Contact Us

you can contact the after-sales engineer

- 200000+

- Favorite Choice For Home Customers

Zhongyi Machinery has won worldwide acclaim with its good reputation, excellent quality, and sound after-sales service, shining brightly in numerous domestic and foreign enterprises!

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)